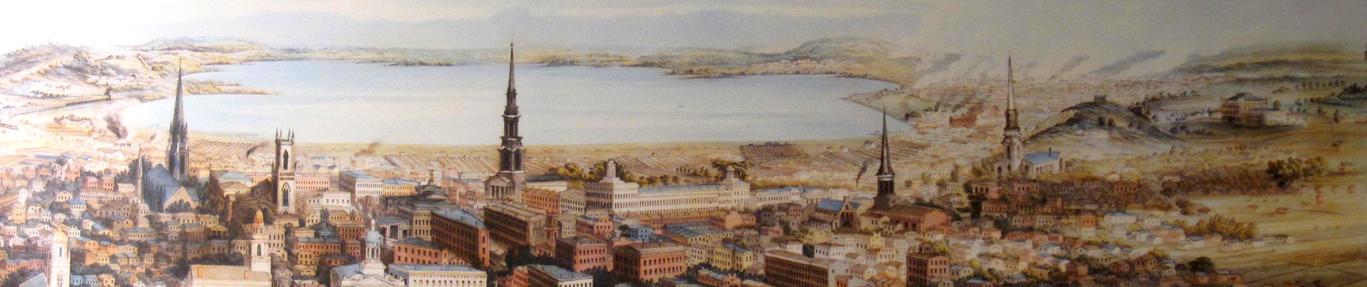

April 2009 saw the end to a 138 year legacy of high-end ceramic production in Syracuse, NY. The Syracuse China Company closed its doors early that year as a cost-cutting move by the company’s owner, Libbey, Inc., of Toledo, Ohio, however, the company’s history and impact are still apparent throughout the city.

Opening originally as the Onondaga Pottery Company (O.P. Co.) in 1871, manufacturing began with only earthenware products. However, with James Pass joining the company in 1885, he developed a new translucent chinaware that put O.P. Co. on the world map. They were the first company to produce American-made vitreous china by the early 1890s, and by 1895 “Syracuse China” appeared as the back-stamp. All of this led to O.P. Co.’s china being used in hotels, clubs, airplanes, trains, cruise ships, and restaurants all over the world. Part of what made Syracuse China so popular was the specific process and quality control that went into each piece.

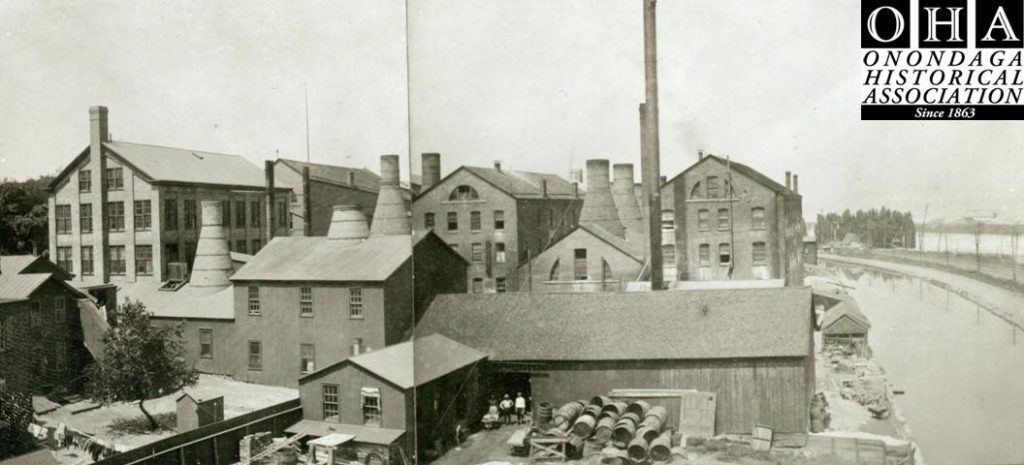

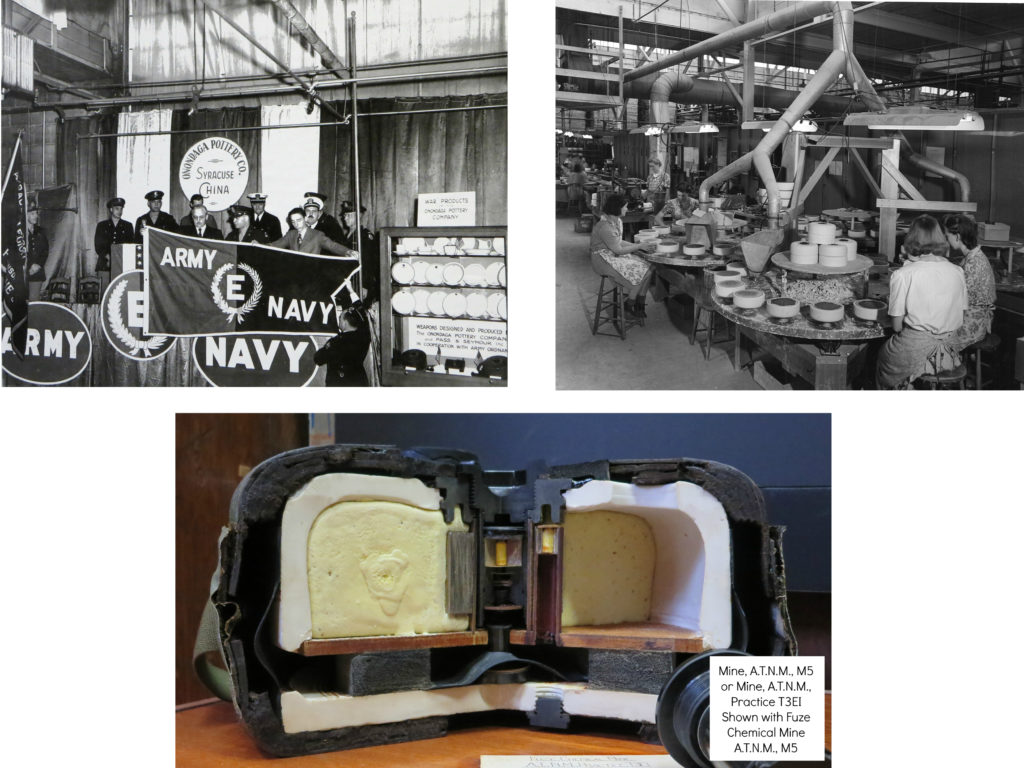

As the company moved into the new century, production increased and two plants were manufacturing ceramic products in Syracuse; the original Fayette Street plant and the newer Court Street plant. With the new century, however, came more world conflict. Once the United States joined its allies in Europe & the Pacific to fight the Axis powers in World War II, the O.P. Co. saw a huge shift in its workforce. Men were quickly shipped off the warfront, leaving behind a predominantly woman workforce in the factories. Along with many other factories nationwide, O.P. Co. jumped into wartime production creating plates, bowls, mugs, and other ceramic wares for the military. O.P. Co.’s most significant wartime contribution, however, was the development of the M-5 anti-tank landmine, a non-metallic landmine that would detonate in any weather, and the M-7 pocket mine, an explosive device that soldiers could carry in their pockets and use as a booby trap and hand grenade. This development was a collaboration with the O.P. Co.’s president, Richard Pass, & company specialists, the Army’s ordnance department, and Pass & Seymour Co. (local electric company).

Top Right: Syracuse China landmine production.

Bottom: Example of a World War 2 Anti-Vehicle Landmine (cross-section).

At the close of the war, the Onondaga Pottery Co. produced almost 60 million pieces of ceramic to the wartime efforts. Men eventually began to return to work, but the workforce at O.P. Co. remained predominantly women. Another large shift happened to the company in 1966 when it was decided that the name of the company be changed to “Syracuse China,” to match its back stamp. The company’s president at the time, William Salisbury, announced the change in name was because of “the broad national and international identification of the product name with the company.”

The Syracuse China Company continued to produce ware all the way up to its final day of production, April 6th, 2009. The 275 employees who worked at the Court Street factory were devastated by this closure, as many of them had more than 20 years of service at the company. Upon closing, all of the business records & documents, decals & other designs, tools, and tens of thousands of pieces of ware were acquired by the Onondaga Historical Association for preservation and interpretation. All unique and significant pieces were accessioned into the collection and, some, are on display in the permanent Syracuse China exhibit. The rest of the pieces, which were never accessioned, are for sale in the gift gallery as whole pieces or turned into beautiful pieces of wearable jewelry, as a way to continue the 138-year tradition of selling Syracuse China here in Syracuse.