Way back in 1868, two Syracusans, G. Lewis Merrell and Oscar F. Soule, formed a partnership and opened a factory for canning fruit and vegetables. Within a year, the two men enlarged their small factory on West Fayette street in Syracuse, and with additional success, they opened plants in Fayetteville and Chittenango. Merrell also invented labor saving canning machinery that helped keep the expanding company competitive. In 1873, the company patented a process for canning corn, the grain being harvested from about 1,500 acres of company owned land. An early company logo featured Captain Samuel George of the Onondaga nation.

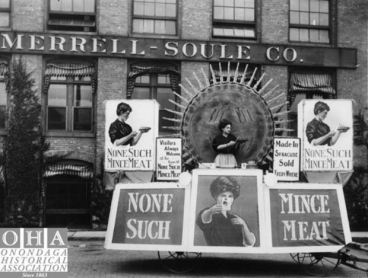

In 1885, the Merrell-Soule Company began making its famous None Such condensed mincemeat. Traditional fresh mincemeat spoiled quickly until Merrell-Soule discovered how to reduce its moisture content. Less moisture in the mincemeat greatly increased its shelf life. The product was an instant hit with dessert and pie makers, and by 1925, the company produced enough mincemeat to fill 12 million pies!

14 years later, Merrell-Soule developed a method for drying milk and began creating Klim (milk spelled backwards) powdered milk. Klim powdered milk was sold throughout the world. After a powerful earthquake devastated the Japanese cities of Tokyo and Yokohama in 1923, Merrell-Soule shipped tons of powdered Klim milk to feed the survivors. Consumers also could find Klim in other parts of Asia, Europe, and Africa, as well as on airlines and steamships. Merrell-Soule also marketed powdered lemon extract and powdered eggs. At its peak in the 1920s, Merrell-Soule had 26 American and Canadian factories and employed 900 people, about half working in Syracuse.

In 1928, the Borden Company purchased the facilities and products of the Merrell-Soule Company. Borden retained the Syracuse plant, and continued to make the world-famous None Such mincemeat there. In 1948, the Borden None Such Mince Meat plant saluted the City of Syracuse for 100 years of progress and proudly looked forward to “Syracuse’s continued growth as a manufacturing and distributing center.” In 1957, Borden spent a million dollars to expand the five-story factory, built in 1904 on Franklin and Plum Streets, to accommodate a research and development center. Also that year, Borden began to build an ice cream factory at the intersection of East Molloy and Thompson Roads.

Borden moved its mincemeat factory from Franklin St. to Wellsboro, PA in 1981, when only 43 employees had been working at the plant. The research center remained open, developing new consumer products. The ice cream factory also remained open, employing about 65 people. However, Borden moved the research center to Columbus, Ohio in 1997, claiming that the Syracuse center needed updating and was too far removed from other Borden facilities to remain viable. About 60 Syracuse employees were offered new jobs in Columbus. Today, the Borden ice cream factory on East Molloy Rd. is listed as Borden Inc. / Dairy Division and is a privately owned, wholesale dairy products company.

However, the legacy of None Such Mincemeat lives on! The world famous condensed mincemeat used by dessert and pie makers for over 125 years is still available at local supermarkets. As we look forward to Thanksgiving 2015, thousands of pie makers will, probably unknowingly, pay tribute to Syracuse’s contribution to the “Prince of Pies!”

–Thomas Hunter, OHA’s Curator of Collections